11 Aug How to Print an Instruction Manual

Instruction manuals can save your customers a big headache when they’re assembling or troubleshooting one of your products. But the readability of your instructions isn’t the only important element to consider when designing a manual.

The choices you make when it comes to printing can make or break your instruction manual. Selecting the best binding, finish, cover, fonts, and other crucial elements can help ensure a positive user experience. Here’s how to print a manual that best serves your customers.

Five Tips for Printing Helpful Instruction Manuals

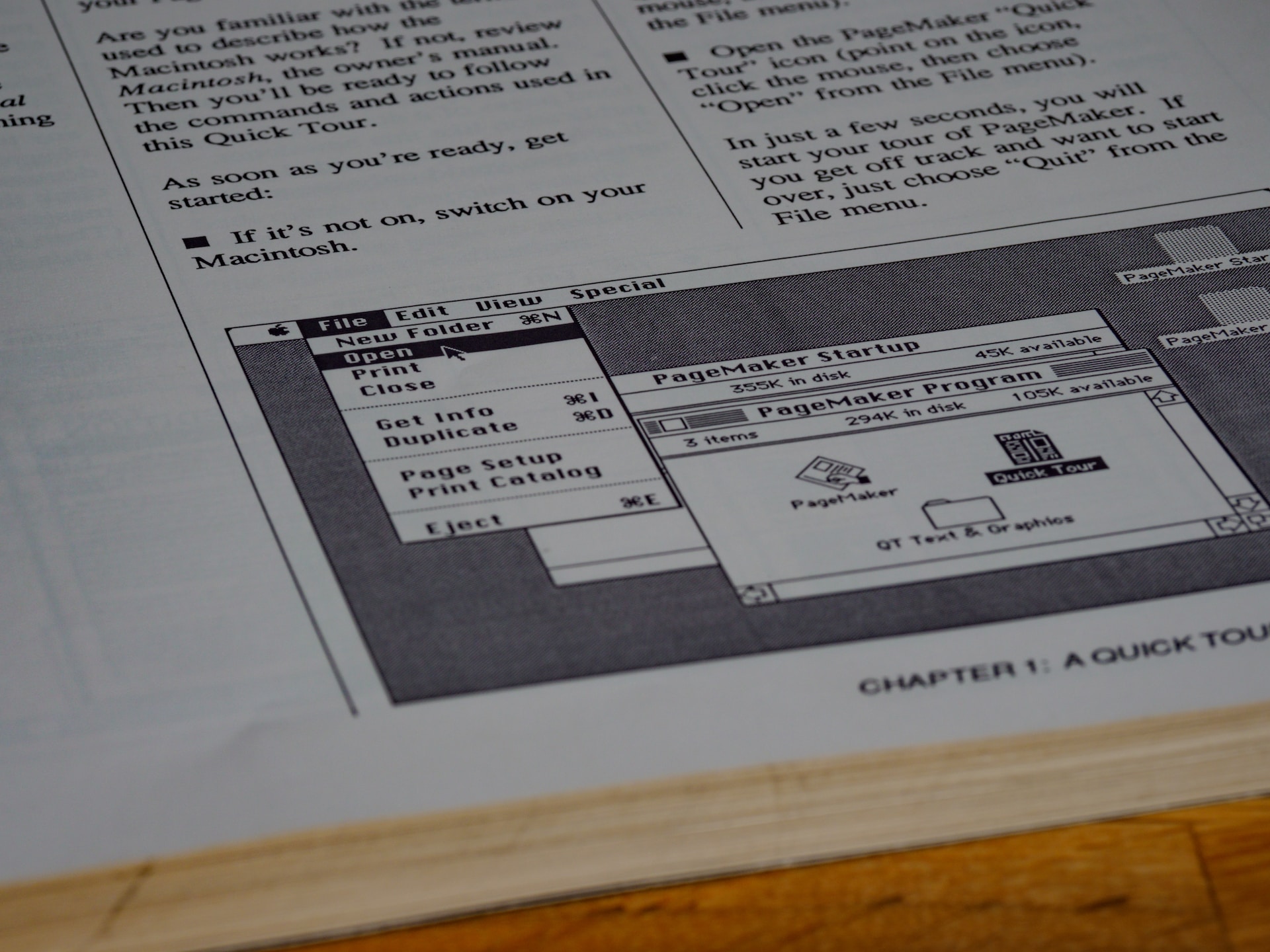

1: Choose an Easy-to-Read Font

Obviously, an instruction manual needs to be easy to read to be effective. But there’s much more to it than organizing information and providing visuals. You also need to consider the type of font you use.

For example, intricate fonts can be messy and hard to read. And light fonts on a light background can be difficult on the eyes. Plus, you don’t want your customers to have to squint to read.

To improve the readability of your text, keep it basic. Use standard fonts like Arial or Times New Roman, use a comfortable size like 12-pt, and use high-contrast color combinations or stick to black and white.

2: Understand Your Paper Options

There are many types of paper to choose from when printing an instruction manual, such as premium gloss, premium matte, or natural stocks. However, synthetic paper stock can be the best option for manuals because it is extremely durable and doesn’t need to be laminated. While laminate finishes can improve the lifespan of other paper stocks, the cost of lamination can quickly add up for high-volume print jobs, and the set-up charges for low-volume jobs can make a very narrow sweet spot for lamination being cost-effective.

3: Decide on a Cover

The cover for an instruction manual doesn’t need to be particularly glamorous. But it should still be visually appealing if you want people to read what’s inside. When you’re designing the cover, try using graphics, product images, or brand elements to make it more engaging.

It’s also best to choose a durable material for the cover, especially if your customers will need to keep the manual for years. While a soft cover is more affordable, hard covers and plastic covers last longer and offer better protection.

4: Choose the Right Binding

Each binding method has unique benefits, so you’ll need to decide which one will work best for your manual. For instance, perfect binding holds the pages together by gluing them to the spine. This method is ideal for higher page counts and is long-lasting.

Saddle-stitching creates a spine by folding the pages in half, and stapling along the fold—like a magazine or comic book. This type of binding makes manuals easy to use hands-free because they lay flat when open. Saddle stitching is best for small, single-use manuals.

5: Proofread Thoroughly

Before you print any kind of document, triple-check to make sure all of the information is correct. Instruction manual errors can be frustrating and even dangerous for users. Make sure to proofread your manual thoroughly—even one error could mean having to reprint the entire batch.

Instruction Manual Printing in Tempe, Arizona

Choosing the right designs and materials can go a long way in improving the customer experience. That’s why it’s important to work with an experienced print shop. The team at Mousegraphics can help you choose the perfect finish, binding, and cover to make your instruction manual more user-friendly.

Give us a call at 480-470-7438 today to request a quote.

Images used under creative commons license – commercial use( 8/11/2023). Photo by Brett Jordan on Unsplash